Optimal Timing for Lead Paint Abatement

Spring offers mild weather conditions, making it ideal for lead paint abatement projects without weather delays.

Summer provides longer daylight hours and stable weather, facilitating efficient and timely lead paint removal.

Fall allows for completion before winter, with cooler temperatures reducing the risk of paint deterioration during removal.

Lead paint abatement is a critical process aimed at eliminating lead-based paint hazards from older structures. Exposure to lead paint can cause serious health issues, especially in children and pregnant women. The timing of abatement projects can influence their effectiveness and safety. Understanding the optimal periods for conducting these projects ensures minimal disruption and maximum safety.

Ideal weather conditions, such as low humidity and moderate temperatures, are essential for safe and effective lead paint removal.

Scheduling during times when buildings are unoccupied minimizes exposure risks for residents and workers.

Larger projects benefit from seasons with predictable weather, reducing delays and ensuring compliance with safety standards.

Timing may also depend on local regulations and deadlines for hazard mitigation.

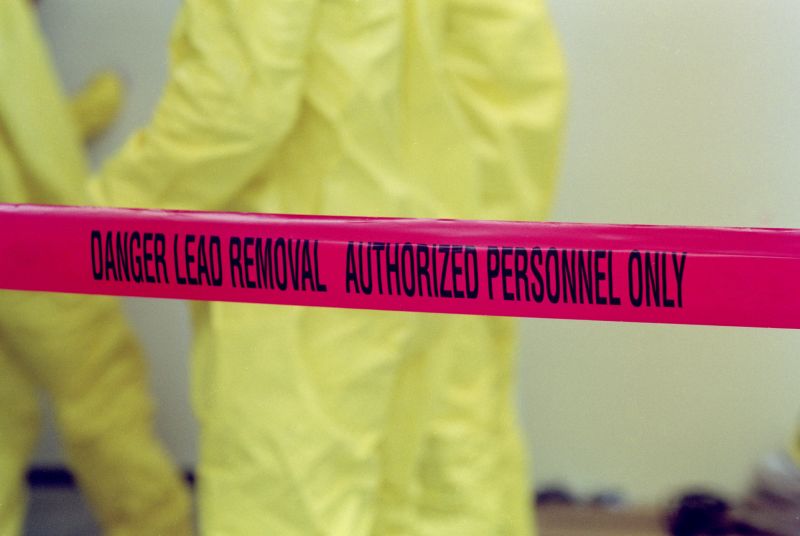

Technicians carefully remove lead-based paint using specialized equipment and procedures.

Preparation includes sealing off areas to prevent lead dust dispersion during removal.

Thorough cleaning ensures no residual lead dust remains after the project.

Workers utilize protective gear to prevent lead exposure during abatement.

Effective containment prevents lead dust from contaminating other areas.

| Timing Factor | Details |

|---|---|

| Weather Conditions | Optimal conditions include low humidity and moderate temperatures to facilitate safe removal. |

| Occupancy Status | Abatement is best scheduled when buildings are unoccupied to reduce health risks. |

| Project Size | Larger projects benefit from seasons with predictable weather for efficient completion. |

| Regulatory Deadlines | Timing may be influenced by local laws requiring hazard mitigation within specified periods. |

| Material Condition | Paint in poor condition may require urgent removal regardless of season. |

| Availability of Contractors | Scheduling depends on contractor availability during certain times of the year. |

| Budget Cycles | Funding timelines can dictate when abatement projects commence. |

| Environmental Factors | Consider factors like wind and rain that can impact safety and project quality. |

Lead paint abatement involves removing or encapsulating lead-based paint hazards to prevent exposure. The process includes careful planning, specialized removal techniques, and thorough cleanup. Proper timing ensures safety, compliance with regulations, and minimizes disruption to occupants. Awareness of seasonal and environmental factors enhances project success and safety outcomes.

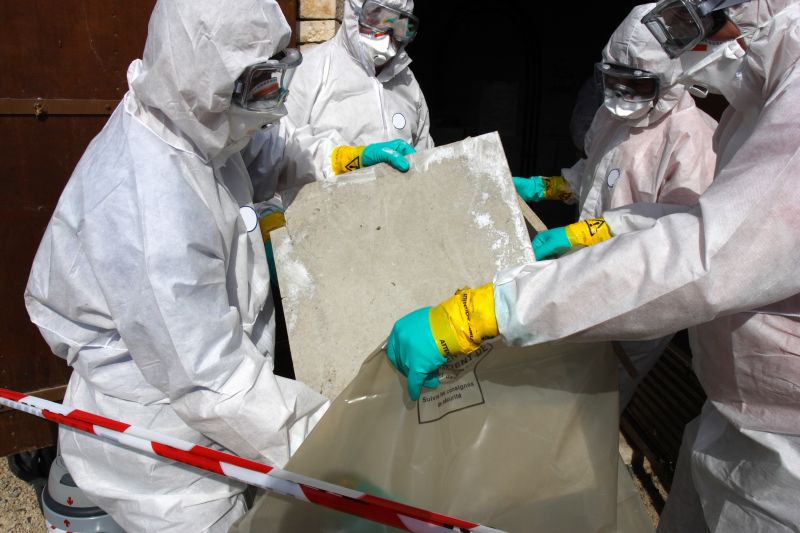

Specialized tools are used to safely remove lead paint without dispersing hazardous dust.

Sealing off work areas prevents lead dust from contaminating other parts of the building.

Protective clothing, masks, and gloves are essential during abatement activities.

Testing confirms the removal of lead hazards before occupancy resumes.

Effective containment minimizes lead dust spread during removal.

Lead debris is disposed of according to hazardous waste regulations.

Inspectors verify that lead hazards have been adequately mitigated.

Clearance procedures ensure the safety of future occupants after abatement.

Choosing the right time for lead paint abatement involves considering weather, occupancy, and project scope. Proper planning and execution are essential to ensure safety and compliance. If interested in scheduling lead paint abatement services, filling out the contact form can facilitate the process.